Air treatment

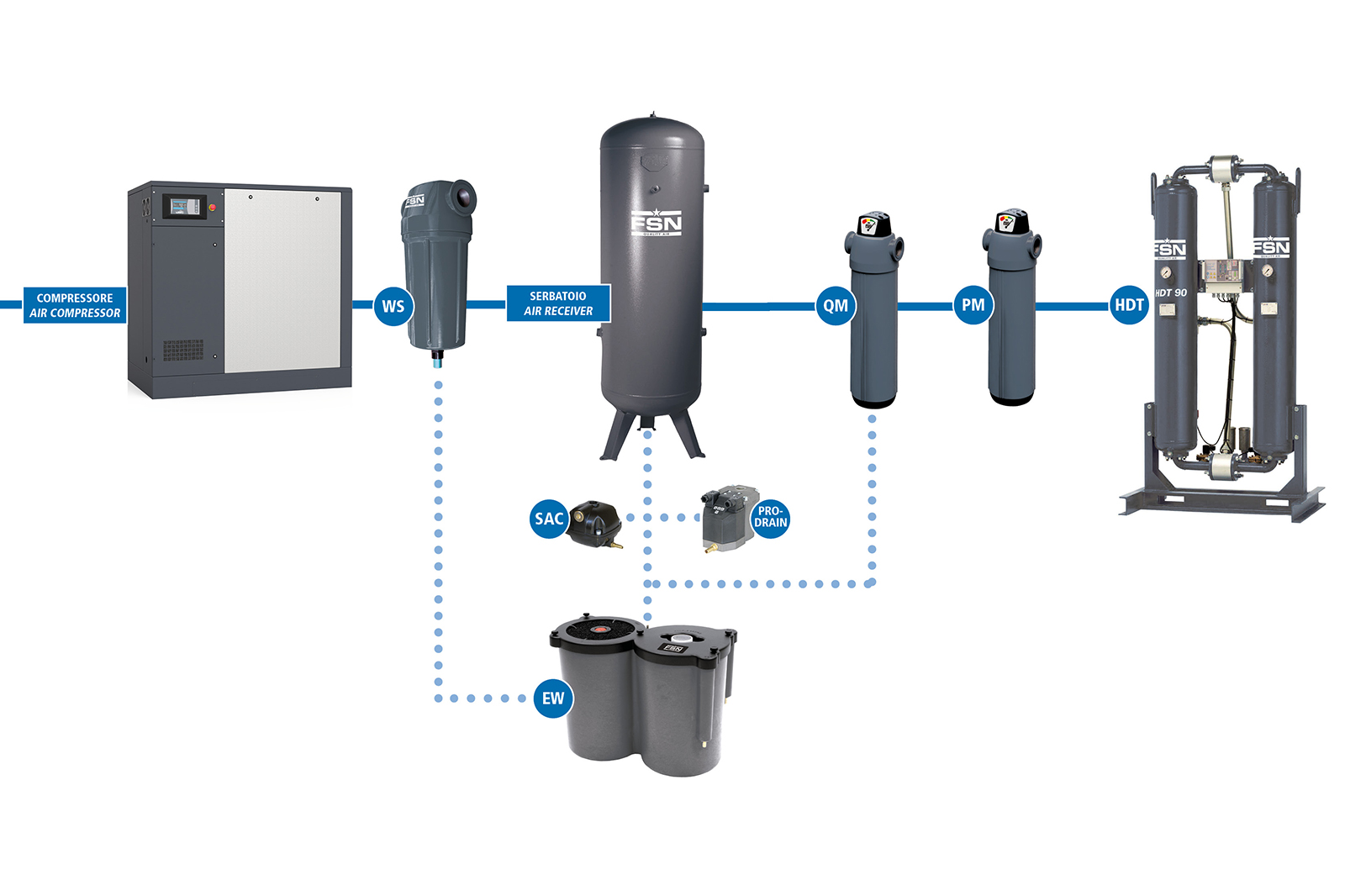

Each process also has its own requirements in terms of compressed air quality. Impurities, moisture and traces of oil can cause contamination of the finished products and deterioration of the distribution lines along the production plant. The choice of compressed air treatment line components depends on the quality required for the smooth running of each company’s production cycle.

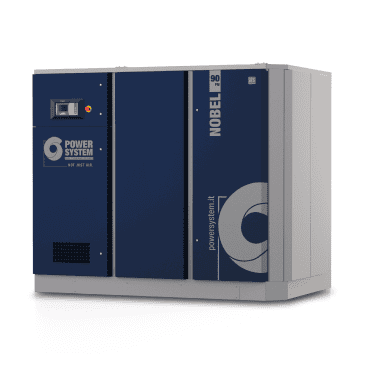

Power System offers a wide selection of products dedicated to this, covering the entire route from the compressors to the point of use.

Typical installations

Scope of application

Medical devices, breathing air, food industries.

Medical devices, breathing air, food industries.

Generic industrial air, air for blowing

Air for control devices, for tools.

Dental laboratories, photographic laboratories.

Fine pneumatics, high quality spray painting, air for surface finishing.

High-quality sandblasting, simple spray painting.

Sandblasting, simple painting

Pneumatic tools, air for control devices, measuring and control systems.

DIN ISO 8573-1:2010

Dust

Water

Oil

1

1-2-3

1

QM: Prefilter

PM: Oil separator filter

HDT: Adsorption dryer (-20/-40/-70 °C)

Compressed air contaminants and purity classes