Rely on our advice.

Relying on a Power System Center for personalised advice means having access to a team of highly qualified and trained experts.

With extensive knowledge and specific experience in the compressed air industry, our team can provide in-depth analysis and a detailed understanding of the opportunities for the company.

Every customer is unique to us and our consultancy is fully customised to meet their specific needs. We work closely together to understand your challenges and develop tailor-made solutions.

We help optimise the use of existing resources: we identify areas for improvement and suggest strategies to maximise efficiency, including energy efficiency.

We constantly monitor market trends, new products and technologies in the industry to ensure the company is as competitive as possible.

Italian company specialising in packaging for cosmetics.

Upgrade and expansion of compressed air production station.

The existing configuration involved the use of single-stage compressors with inverters which, due to their age and the need for extraordinary maintenance, were no longer efficient and reliable.

Audit and insertion of a double-stage variable speed NOBEL 2S 132 compressor using existing units as backup machines.

Total energy consumption reduced by 3% above the audited value.

Azienda leader nella produzione di laminati plastici in PET e PS per l’imballaggio alimentare e farmaceutico nel nord Italia.

Aggiornamento e ampliamento stazione produzione aria compressa, inclusi i sistemi di trattamento aria.

La configurazione esistente prevedeva l’uso di compressori monostadio con inverter che, per età e necessità di manutenzione straordinaria, non risultavano più efficienti e affidabili.

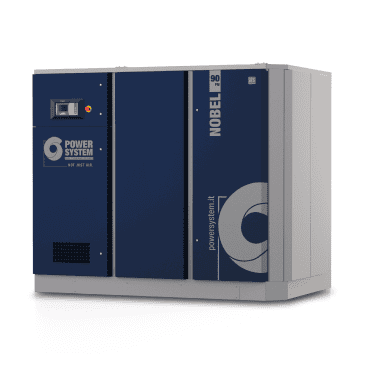

Sostituzione della macchina esistente da 110 kW con una nuova NOBEL 90 2S da 90 kW.

Gli strumenti di misura dell’energia assorbita già installati dall’azienda hanno confermato risparmi di oltre il 30% rispetto alla configurazione originaria.